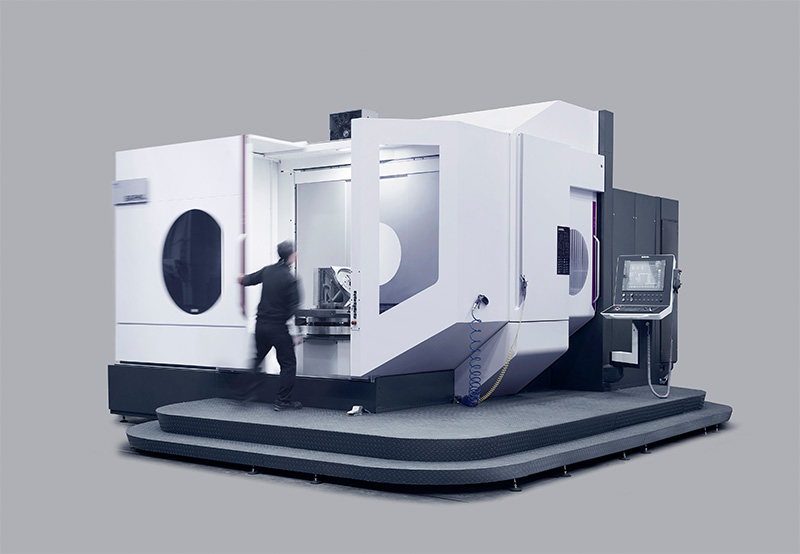

Ex Stock Ibarmia THC12 Extreme Twin Pallet 5 Axis Universal Machining Centre

Machine Information

In stock and available for immediate delivery, 5 axis machining of large parts, increasing productivity with multitasking technology and automation systems

Machine Features

Huge capacity 5 axis capability

Fanuc 31i-B control

60 tools

Twin pallet

| X axis longitudinal | 1200mm |

| Y axis transversal | 1100mm |

| C axis table | 360° |

| Table dimension | 800 x 800mm |

Related products

-

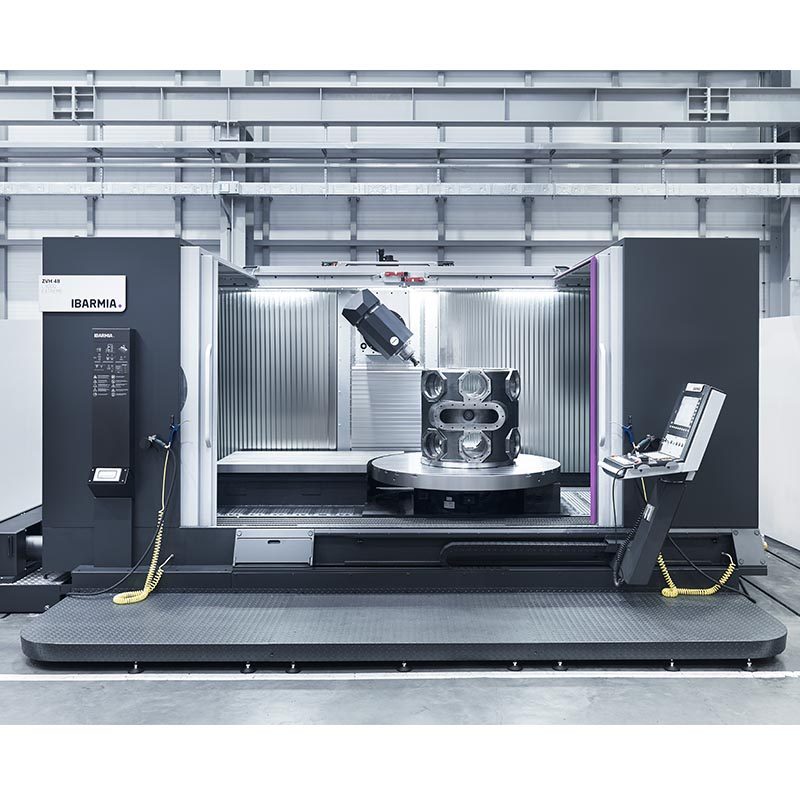

Ibarmia Z Series Travelling Column 5 Axis Machining Centres

FIND OUT MORE3, 4 and 5 axis machining centers with very flexible configuration, available with built in rotary tables for 5 axis machining and vertical turning

-

Dugard GTX-650 5 Axis Vertical Machining Centre

FIND OUT MOREMade in Taiwan. Five axis VMC 12,000rpm spindle speed, 620/520/460mm X/Y/Z axis, 25/25rpm tilting/rotary axis speed, Ø620 x 330mm maximum workpiece size

-

Kitamura Mytrunnion-7G 5 Axis Vertical Machining Centre

FIND OUT MOREArumatik-Mi control, X axis 1190mm, Y axis 1380mm, Z axis 765mm, Ø1000mm table size, 2000kg table load, BT50, 100 tools, 4th and 5th axes.

-

Kitamura Supercell-400G 5 Axis Horizontal Machining Centre

FIND OUT MOREArumatik-Mi control, X axis 510mm, Y axis 510mm, Z axis 510mm, Ø350mm pallet size, 80kg pallet load, BT40, 20 pallets (up to 80 opt), 140 tools (up to 290 opt)

Superior-quality CNC Machines

Made in Spain

SPECIFICATION

| X axis longitudinal | 1200mm |

| Y axis transversal | 1100mm |

| Z axis vertical | 1000mm |

| NC head tilting range | -15°/+195° |

| C axis, table | 360° continuous |

| Max swind diameter | Ø1200mm |

| Max height of piece | 1250mm |

| Table dimension | 800 x 800mm |

| Max table load | 4000kg |

| Max speed | 8rpm |

| Nominal torque | 2800Nm |

| T-slots | 7-100 x 18mm |

| Spindle nose to table - vertical | 100/1100mm |

| Spindle nose to table - horizontal | -200/900mm |

| Taper of tool holder axis | ISO50 |

| Tool holder pull stud | DIN 69871 |

| Position clamping force | 6000Nm |

| Turning motor torque (continuous turning) | 744Nm |

| Electrospindle power in service S1 (100%) | 48/74kW |

| Electrospindle power in service S6 (40%) | 71/84kW |

| Torque in service S1 (100%) | 300/177Nm |

| Torque in service S6 (40%) | 452/200Nm |

| Max rotation speed | 12,000rpm |

| Digital servomotors with incorporated break system | |

| X axis rapids | 40m/min |

| Y axis rapids | 30m/min |

| Z axis rapids | 4m/min |

| X axis working feed | 30m/min |

| Y axis working feed | 30m/min |

| Z axis working feed | 30m/min |

| Positioning speed on B axis | 50rpm |

| X axis rollers | 3+3 |

| Y axis rollers | 2+2 |

| Z axis rollers | 2+2 |

| X axis between linear guides | 980mm |

| Y axis between linear guides | 660mm |

| Z axis between linear guides | 710mm |

| Roller dimensions | 55mm |

| X axis ball screw dimension | D63/P25mm |

| Y axis ball screw dimension | D63/P30mm |

| Z axis ball screw dimension | D50/P25mm |

| Milling capacity in steel 600 N/mm2 | 1100cm3/min |

| Drilling capacity in steel 600 N/mm2 | Ø70mm |

| Tapping capacity in steel 600 N/mm2 | M-45mm |

| Positioning accuracy Tp X-Y-Z (1000mm) | 10µm |

| Positioning repeatability | 5µm |

| Positioning accuracy B axes | 100"s |

| Number of tools | 60 |

| Max tool dia adjacent occupied | 125mm |

| Max tool dia adjacent empty | 250mm |

| Max tool length | 450mm |

| Max tool weight | 20kg |

| Tool management system | random |

| Tool change time | 6"s |

| Chip to chip time | 8"s |