BRAND

WORKING ALONGSIDE

Since 2019

ESTABLISHED

In 1933

ACCREDITATIONS

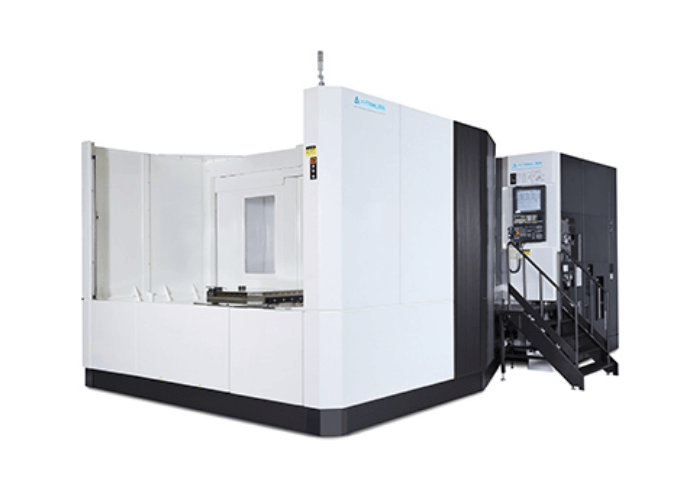

The Best Kept Secret from Japan with over 30,000 machines installed worldwide

Feature exceptional quality, accuracy and rigidity as standard as well as high speed travels, choice of spindles up to 30,000rpm and 1000Nm torque. All machines are built using the “True Geometry System”