Unilathe turns to Dugard

As a supply chain partner to a multitude of blue chip OEMs that are household names, Unilathe has been providing a complete engineering service to industry since its inception in 1977. Applying the latest generation of machine tools, the Stoke-on-Trent Tier 1 subcontract manufacturer has recently invested in a Kitamura Mycenter HX500iG horizontal machining centre from Dugard Machine Tools to add to its three previously installed Kitamura machines.

As a company that specialises in the oil and gas, rail, construction equipment, IGT and aerospace industries, Unilathe installed its first Kitamura machine more than 11 years ago. Recalling the start of the Kitamura journey, Unilathe’s, Andrew Sims says: “The first Kitamura machine we bought 11 years ago was a secondhand machine. That dipped our toe in the water with Kitamura with regards to the twin box way slides, the high speed and rigidity. In fairness, the performance and the reliability we got from that machine, really started to pave the way for us to look at what we should be doing with our machine tool purchasing strategy. We started asking whether we should go down a one-brand machine purchasing process, not only with regards to brand but also the specifications and the right technology perspective.”

Following the first Kitamura Mycenter, Unilathe has since invested in two horizontal Mycenter 630iG machines from Dugard in 2018 and 2019 respectively – with the latest Kitamura Mycenter HX500iG being commissioned at the start of 2021.

“We are Tier 1 supplier to major OEMs throughout the UK, Europe and worldwide. So, generally speaking, we machine a lot of gearbox components and other parts from cast iron, cast steel and other materials where rigidity and performance, coupled with high-speed and advanced technology is really crucial. The Kitamura machines from Dugard really fits the bill. When we are looking at new machines, the main consideration for us is reliability, speed, performance and accuracy – as we have to machine these components in the most competitive nature possible whilst maintaining very high quality. At the moment, we are currently running 100 hours a week with a day and afternoon shift with weekend work – but if we need to get up to 24/7, the Kitamura’s will certainly do it,” says Mr Sims.

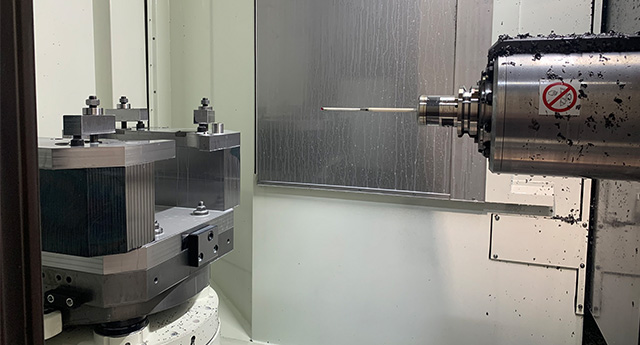

The latest Kitamura to land at Unilathe, the BT50 spindle taper Mycenter HX500iG has a 500 by 500mm table and axis travel of 870 by 930 by 500mm in the X, Y and Z axes. The accuracy and repeatability noted by Mr Sims is demonstrated in the 0.001 degree indexing of the 4th axis, spindle and tool probing, zero backlash, built-in encoders, linear scale feedback and a host of other high-precision features that are guaranteed to perform. This precision and repeatability assurance is provided by patented twin ballscrew system that has ballscrew cooling, hand-scraped surfaces, induction hardened boxways and much more.

Commenting on the twin pallet Mycenter HX500iG, Unilathe machine operator Louis Purchase says: “There are so many things I like about the Kitamura machines. The speed is incredible – the speed is actually scary, that is the best way to describe it! I have been at Unilathe for over three years and worked on a wide variety of machines, but I have never seen anything like the new Kitamura machines. I have also worked on the older Kitamura machines, but the speed of the rapids on the latest machines is absolutely incredible.”

Underpinning this testament to the speed of the Kitamura brand is class-leading 60m/min rapids and cutting feed rate with a B-axis rapid of 43,200 deg/min with an 8.8 second pallet change and 2.1 second tool change time.

The majority of the work on the new Kitamura machines at present is cast iron components for the agricultural industry. Alluding to this, Louis says: “I work across the latest Kitamura machines we have here, and they just tear through cast-iron – that’s the best way to describe it. We are machining a range of different parts and there is flexibility and interchangeability between the 630iG and 500iG machines. In addition, the tool carousel moves extremely quickly and when it comes to production jobs, you want accuracy, and you want speed – and you have both of them with the Kitamura Mycenter machines.”

The new Kitamura additions also incorporate probing, referring to this, Louis says: “The probing ensures we have complete consistency. With the probing system, we know that the last job in a production run will be the same as the first-off because you are probing your datums on every single job.”

Regarding the precision turned parts machined at Unilathe that are then transferred to the Kitamura Mycenter machines, Louis states: “The turned parts are held to tight tolerances before loading on the Kitamura machines, so if we didn’t probe the jobs every single time, we would not be able to guarantee that the job will come off the Kitamura machines the same every time. However, having the probing system means that we know the exact tolerances that the part has been turned to and its positioning on the Kitamura machine before we start machining.”

“Additionally, the Kitamura’s have a ‘tool life calculation system’ incorporated into the machines and this is perfect for production jobs. Essentially, it counts how many jobs each tool has done. This is hugely helpful for production when you are using a lot of tools. You calculate a tool life parameter and once the tool has hit this parameter, you are notified to change the tool or inserts, re-set the tool and you start again. For example, we may calculate the tool life based on 10 production run components. Whilst we know that anything can happen in engineering, the system is always right, and it helps with long-running parts. This is another feature that is all about speed and ease-of-use, which is the best way to describe the Kitamura machines.”

Taking a closer look at the work envelope of the BT50 spindle Kitamura Mycenter HX500iG, Louis comments: “The work envelope is very easy to access – it’s just dead simple. Everything turns very easily, and we can access the part without problems, it’s just a delightful machine to work on.”

From a productivity standpoint, the Kitamura Mycenter HX500iG is a twin-pallet machine – this minimises downtime for the Staffordshire company. “The twin pallet allows us to run two different jobs at the same time and this flexibility enables us to double our production output.”

Commenting on the ease of use, Louis says: “The new Kitamura machines have probably been the easiest machines that I have worked with so far. The Arumatik control panel is intuitive and guides you through all the steps and this makes it easier for everyone, regardless of whether you’re an engineer with 20 years’ experience or somebody that is just started CNC machining. The touchscreen configuration is very easy to use, but one thing that I really like is that it has a PC keyboard. This means that if you are typing anything in it is so much faster to use, as everybody nowadays has an understanding of a keyboard and the position of the keys.”