BRAND

WORKING ALONGSIDE

Since 2018

ESTABLISHED

In 1952

ACCREDITATIONS

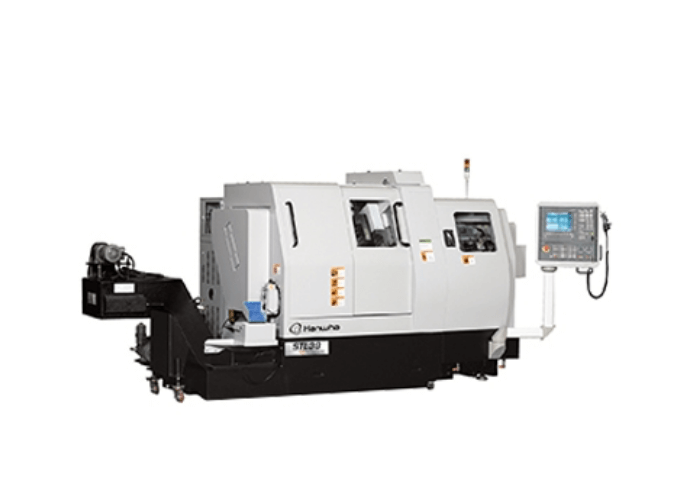

Hanwha sliding head CNC lathes have a full line-up, ranging from 3 to 42mm, featuring high-grade CNC units, complex tooling and high-rigidity machine structure for complex and precision machining.

Hanwha patented PCR3 Chip Breaking Software

1. Included as standard equipment

2. Available on all axes

3. Can be used on main & sub simultaneously

4. Will work at feed rates up to 2mm/rev

5. Also applicable to Threading, Angles, Tapers and Radii

The Hanwha sliding headstock machines offer a varied range of models with optimised design combinations as per customer requirements.

Hanwha lathes are 20-30% heavier than competitors' machines of similar capacity. Customers are reporting massive improvements in the realms of heavy cutting, tool life and cycle times, giving up to 30% improvements on all these functions.